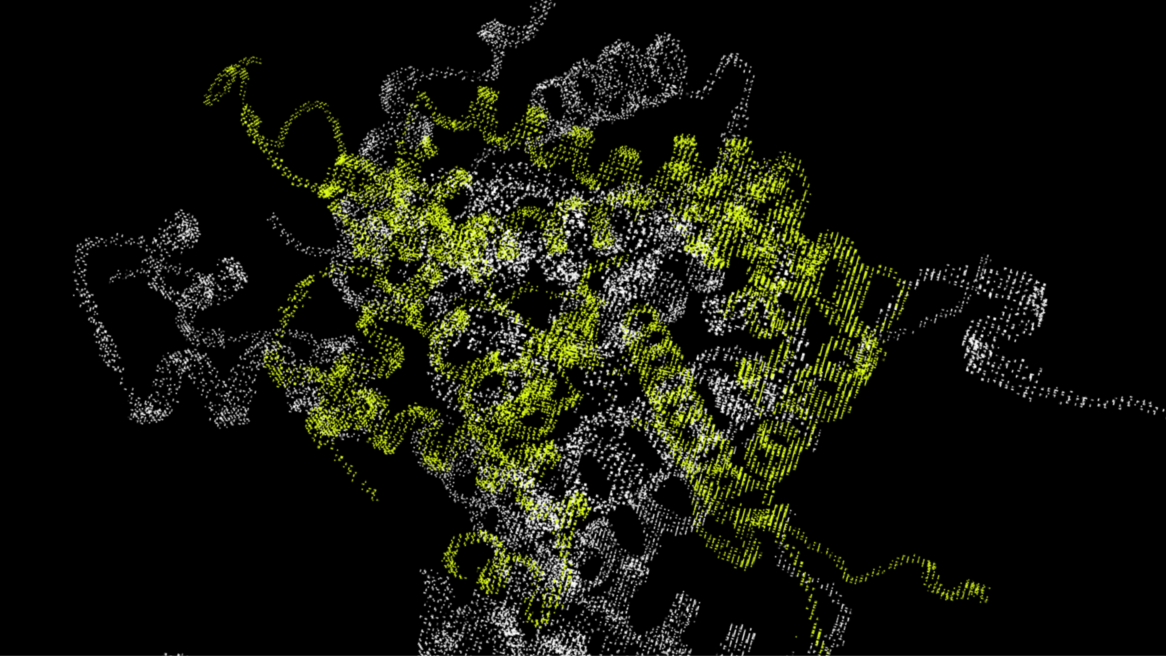

EziG, enginzyme's proprietary technology, enables the creation of heterogeneous catalysts by immobilizing enzymes onto a solid, but very porous material. The end result is a powder.

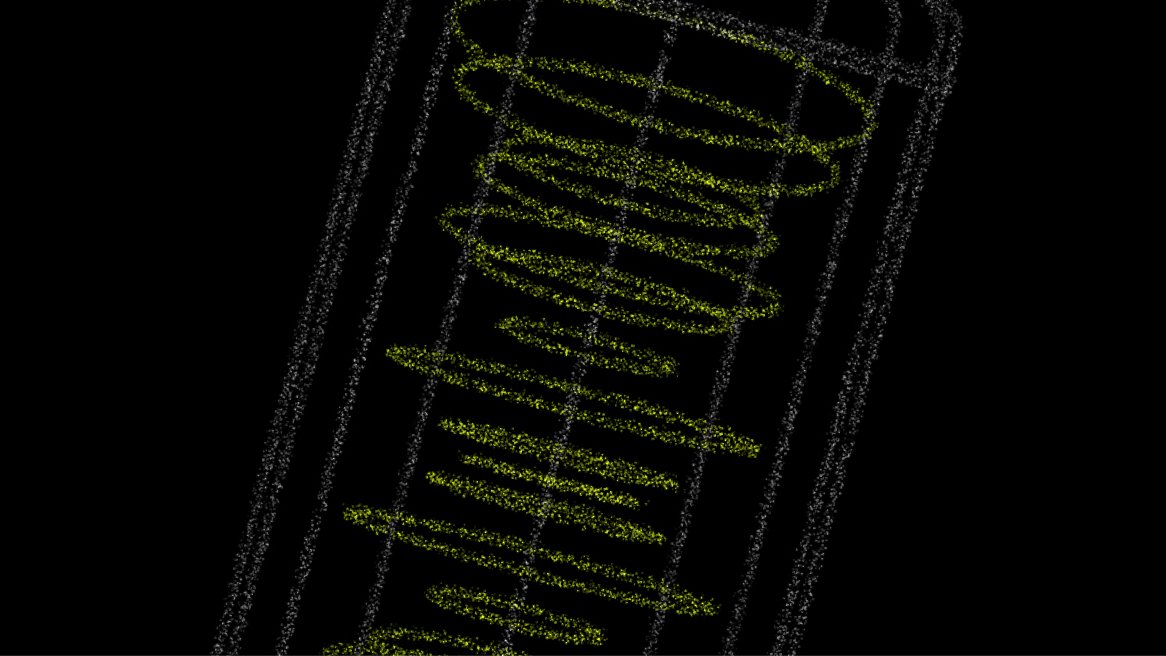

Taking enzymes out of their cellular environment and fixing them onto the EziG material enables the creation of enzymatic cascades in fixed-bed reactors. These are sequences of successive enzymatic reactions where the output of one reaction is used as the input for the next.

The key here is the improvement in enzyme stability, which allows for extensive reusability and much lower operating costs. By using this technology, enginzyme creates bespoke heterogeneous catalysts that are similar to those well-understood in the chemical industry.

A heterogeneous catalyst is a type of catalyst that exists in a different phase (solid, liquid, or gas) than the reactants in a chemical reaction. This distinct phase difference allows the reactants to interact with the catalyst surface where the catalytic reaction occurs.

For example, in a reaction involving gas-phase reactants, a solid catalyst can be used. The reactants adsorb onto the solid surface, react, and then the products desorb, leaving the catalyst surface ready for another cycle.

The key features of heterogeneous catalysts include:

Surface Area: The effectiveness of a heterogeneous catalyst often depends on its surface area. Greater surface area allows more reactant molecules to interact with the catalyst simultaneously, enhancing the reaction rate. EziG is engineered to provide greater surface area when needed — we can create EziG particles of different sizes depending on the reaction we are looking for and the characteristics of the enzyme.

Ease of Separation: Since they are in a different phase, heterogeneous catalysts can be easily separated from the reaction mixture. This is beneficial for industrial processes as it simplifies product purification and catalyst recovery.

Reusability: Heterogeneous catalysts can often be reused or regenerated, which is economically advantageous for industrial processes.

Stability: They are generally more stable than homogeneous catalysts under reaction conditions, which can be important in high-temperature or high-pressure processes.

enginzyme's immobilization technology enables compatibility with most modern infrastructure. This facilitates easy and reliable production scale-up. The application of flow chemistry offers benefits like higher throughput, improved quality, and lower energy consumption.